Machine Parts For Reuse Newsgroup Discussion Forum > Small Size Parts

> Used

> Mechanical

> Cleveland

> Vacuum table 2818 seal cnc engraving or milling machine

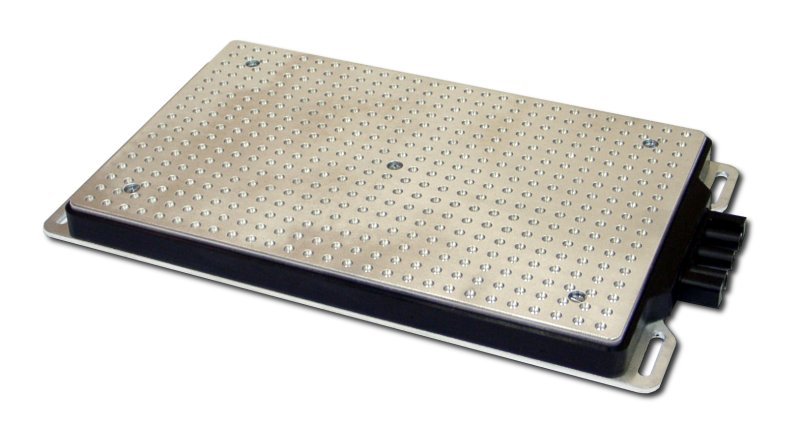

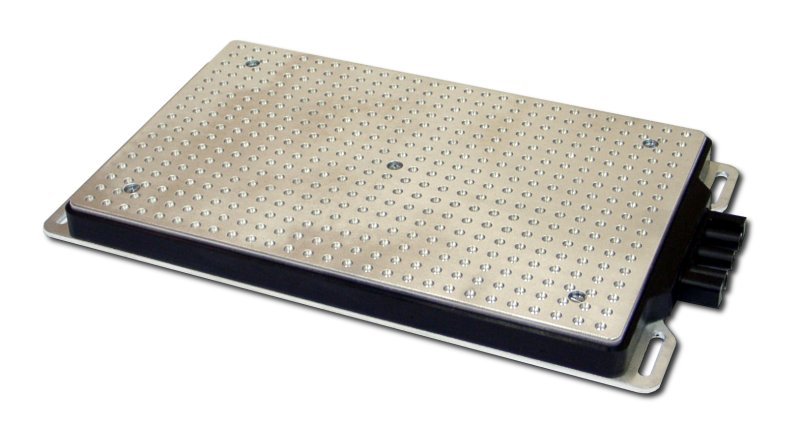

Vacuum table 2818 seal cnc engraving or milling machine

Vacuum Clamping Table VT2818SEAL

The vacuum table for wet and dry clamping

New! New! > Visit our onlineshop onlineshop. < New! New!

The sale of such equipment or tools is a matter of trust! This vacuum table is a real tool of the industry, since everything you see that looks like aluminum is aluminum! By means of the videos and pictures found below, one can be convinced of its asthonishing capablities.

This table is the ideal solution for clamping using pretty much all materials that can be automatically or manually worked on with a CNC machine. Typical fields where this can be used is electronics, electrical engineering, engraving, construction - just any form of clamping. It doesnt matter whether on CNC milling machines, surface grinding machines, Laser cutting machines or simply in the use of measurement engineering. In contrast to a magnet clamping surface plate, with this table you can also clamp non magnetic materials like aluminum, brass, copper and sinthetic materials.

The assembly on the CNC-table takes place selectively by means of the T-slots or based on the assembly socket.

The operation can practically take place via any vacuum pump. First attempts can easily be carried out with a standard vacuum cleaner. An adapter is contained with the delivery.

The retention force is proportional to the covered surface, the frictional coefficient and the differential pressure. To raise the frictional coefficient, a hole rubber mat is also contained within the delivery. Simultaneously this also serves as a protection for the vacuum plate(surface) when the milling machine operates on a certain workpiece. Rubber hole mats are parts subject to wear and inexpensive to obtain.

In this attempt a "K rcher" vacuum cleaner was used. The measured pressure differencial amounted to solely 152mb. When using a corresponding vacuum pump the retention force increases in the same ratio as the pressure differential does.

(By the way, the old building in the background is not our company.)

When working with metals, or hard to clamp synthetic materials the use of a cooling lubricant is very advantagous. First of all the result will clearly be better, secondly the life of the tool or equipment will be 4 to 5 times longer, and thirdly it can be worked on at dramatically higher speeds. This counts for both highspeed-cutting and conventional milling machines.

This vacuum plate enables to work on wet surfaces with solvent free cool lubricants. One must be beware though when higher amounts of liquid are used, a fluid precipitator can be included optionally. It would then come between the table and the vacuum pump. After the assembly, the vacuum plate must be programmed to reach only an accuracy of less than 50 , for this reason its meaningful to select the size of the vacuum table a little smaller than the procedure way of the machine to be able to cover the whole surface until the edges. Of course we also deliver customized vacuum tables per request.

Here are essential Advantages:

1. Use of high-value materials, hence long-term stability. Working with a wet surface no problem. Clearly faster and more efficient then using synthetic materials.

2. Multi-Functional vacuum plate, register pins can be set in place, which enables a flawless reproducibility when doing a batch(series) production. Slight air consumption by the highest possible retention force, by which you get a good efficiency with uneven materials or when using a high pressure vacuum pump.

3. Very low height of only 27mm, thus not losing much working room for the Z-axis.

4. Up to three vacuum tables can be directly connected to the connecting adapater, due to this easily a vacuum field can be constructed without having to switch on each table in a specific order. And when turning the 2nd and 3rd tables on, with each the air revenue is increased.

5. Adjustable connecter adapter can receive vacuum cleaner nozzle sizes of (28mm and 48mm) hose nozzles, therefore super flexible applicability. Reductions would take place, if a narrower diameter has to be used to be received by us.

6. Hole or sinter rubber mats, air permeable rubber mats( with a homogeneous microporous surface) to receive as accessories.

7. Interchangeable vacuum plates, in case a mishap occurs, therefore making it a simple repair.

8. Optimal vacuum distribution through compley canals within the vacuum chamber.

9. High air revenue through broad layout of the connecters

The delivery contains the following:

* 1 x Vacuum table VT2818SEAL

* 1 x Covering rubber mat to cover uncovered space

Still have questions ? - info@vakuumtisch.de

You receive a guarantee of two years on this tables starting after the purchase date. Excluded hereof are mechanical damages through faulty mechanical processing. As a commercial manufacturer, we issue a calculation with the included sales tax.

One month money back guarentee: In accordance with the export sales law, you recieve one month return the product and get your money back. This only works though, when no traces of use are visible.

Should this vacuum table not meet your requirements, please do not hesitate to contact us directly. This counts especially if you have a regular demand as a manufacturer of machines or equipment and seek a low priced mass production.

Stritzelberger Steuerungstechnik GmbH