Machine Parts For Reuse Newsgroup Discussion Forum > Small Size Parts

> Non functional

> Electronic

> Springfield Ill

> A-prime low flash point solvent precision cleaning sys

A-prime low flash point solvent precision cleaning sys

Forward Technology A-Prime Low Flash point Solvent Precision Cleaning System,

This listing is for a Used Forward Technology precision cleaning system Mfg date of 4/1997

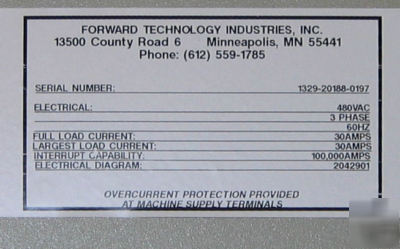

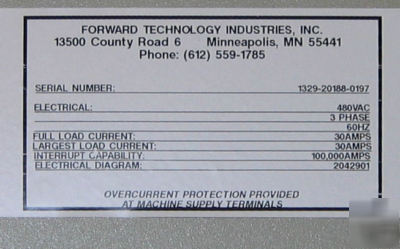

S/N 1329-20188-0197. The machine is in great, working condition when removed from service.

This unit was used to clean precision tooling and only IPA (Isopropyl Alcohol) has been in the system

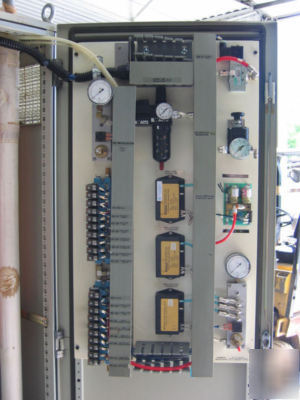

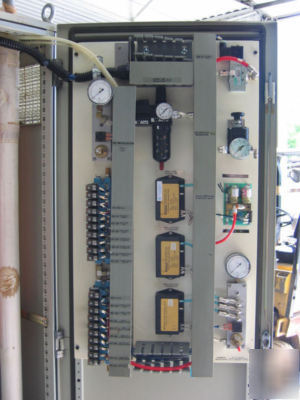

since 1997. This listing includes the cleaning machine itself, the control cabinet,

operating and service manual contain complete electrical and pneumatic schematics for this machine.

The chamber and control cabinet are separated, but the wiring and pneumatics are labeled and there

are reconnection instructions in the Installation Manual. Solvents that can be used in the system include:

Alcohol, Cyclohexane and Alcohol/Cyclohexane Azeotrope . Many other solvents such as Acetone

and volatile methyl siloxanes may also be used in the A-Prime , but should be discussed with the

Forward Technology technical staff and may require system modification. This A-Prime unit is equipped

with the following safety features: Integral CO2 fire detection and suppression system.

Integral gas vapor detection and warning system. Electrical power is removed from the machine

at 25% of the solvents Lower Flammable Limit. Lip and Cabinet exhaust for vapor removal .

Purging of ultrasonic transducers with inert gas. Active cooling of the solvent to limit vapor emission.

Extensive use of pneumatic controls. Electrical circuits are contained in either explosion proof conduit

and /or with intrinsic isolation devices. Materials: all components that contact solvent including tanks,

plumbing and heating and cooling coils are made of 316 or 316L stainless steel . All structural

components including framing, covers and counter tops are constructed of 304 stainless steel.

The system is equipped with a pnematical operated cover that automatically closes when the system is not in use.

The vertical pneumatic lift controls the rate of part travel through the vapor zone to ensure adequate drying and

minimize solvent dragout. The lift is also interlocked to activate the cover when loading and unloading parts,

The lift also transfers parts laterally between the two sumps. Load the parts and push a button , typical applications

include the removal of contaminants from PC boards,Hybrid junctions, Electromechanical components,

Precision mechanical components, Optical instruments and Medicak devices and components.

Cleaning Machine - 45L x 64W x 94H Weight 1840 lbs on skid

Control Cabinet - 55L x 17W x 96H Weight 1110 lbs on skid

The chamber is 25" x 14" x 36" deep and divided at the bottom,

between the Boil Sump and the Immersion Sump

Electrical Information (found on control cabinet nameplate)