Machine Parts For Reuse Newsgroup Discussion Forum > Small Size Parts

> Non functional

> Electrical

> Cleveland

> Jorestech -vacuum chamber food packaging sealer machine

Jorestech -vacuum chamber food packaging sealer machine

NEW - Vacuum Packaging Machine

Package a wide variety of Food Products, Electronic Components and Valuable Documents

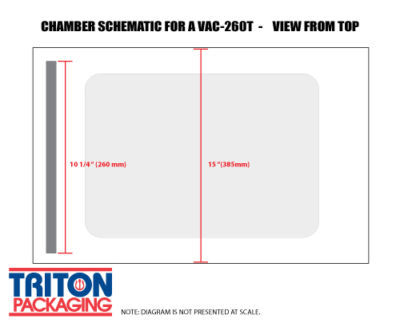

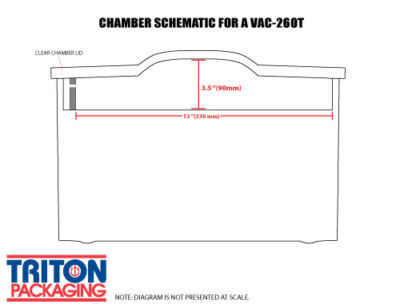

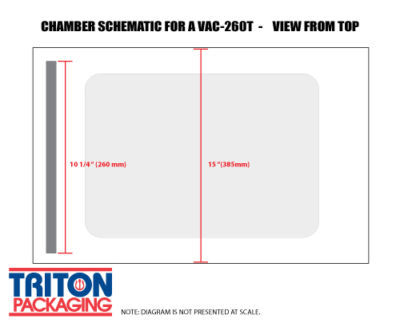

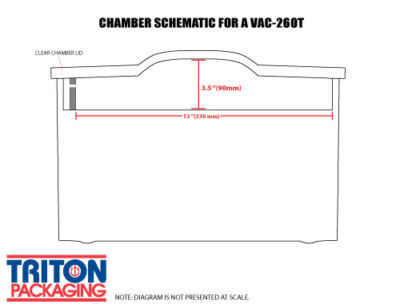

* Chamber Dimensions: 15 (385mm) x 11 (279mm) x 3.5 (90mm)

* Equipped with one Seal Bar with one extra wide Seal Element

* Seal Height: 0.197" (5 mm)

* Seal Width: 10 1/4" (260 mm)

* Triple Temperature Adjustment

* Programmable Vacuum Duration (in seconds)

* Impulse Seal Time Adjustment (in fractions of a second)

* Cool Timer (in Fractions of a second) decreases the risk of seal breach by

* allowing the bag to regain strength through after fusing during the seal cycle

Machine Dimensions: 13 (330mm) x 19 (482mm) x 14 (356mm)

Packaged Dimensions: 19 (483mm) x 25 (635mm) x 19 (483mm)

Packaged Weight: 98 lbs (45 kgs)

Yes, it is designed to seal barrier laminations including laminations containing foils.

How much longer will my products last?

What type of bag do I need to use?

You need bags capable of offering a full gas barrier. Bags come in different sizes, and minimum order is typically only one thousand bags. Contact of us pricing and availability.

What are the advantages of vacuum packaging my products?

No loss of volume or product weight due to evaporation

Reduced action by aerobic bacteria

Ease keeping control of inventory

Cost-reduction due to volume purchasing of products to be packaged

Capacity of producing in large batches

Increased Product Safety from theft, vandalism and contamination.

Improved product quality perception from clients and consumers

The operator places the bags flat onto the work surface of the machine, putting the mouth of the bag on the bottom seal bar. The vacuum pump engages as the operator lowers the lid of the chamber. Once target vacuum level is achieved the machine automatically seals the bag and lets air re-enter the chamber. On double chamber machines, the operator clears sealed bags and places new ones into the empty chamber while the vacuum process takes place on the filled chamber.

You should keep a few Heating Elements and Teflon Strips, as these have a limited life span. The machines come with a kit of spares, but keep an eye on how many you have left.

If I vacuum package my food products, will I still need to refrigerate them?

Yes, vacuum packaging is not a substitute to refrigeration.

My products cannot handle the crushing pressures I see in vacuum packages. Are there any options available?

Yes there are options we can offer. By replacing the air inside the bag with inert gases (which will not interact or affect your product in any way), we can achieve the same results of vacuum packaging while eliminating the crushing atmospheric pressures visible in many vacuum packaging applications. The packing process is the same as the one describe above, with the addition of a gas flush or gas injection phase right before sealing the bag. Contact us for more information on the best model for this application as this feature is not standard.

We offer single and double chamber machines, equipped with single and double seal bars, and different chamber volumes; as well as fully automatic machines designed to cover the most rigorous productions schedules. Check our other listings or contact us for more information. We do not list all of our offerings.