Machine Parts For Reuse Newsgroup Discussion Forum > Medium Size Parts

> Non functional

> Electrical

> Chicago

> .0005" camera cnc cmm xyz machining vision reverse eng.

.0005" camera cnc cmm xyz machining vision reverse eng.

You can have the functionality of both the cnCam-e (0.0002") and the cnCam-d (long distance 0.0005") for the price of one cnCam-d.

cnCam-d will come with the cnCam-e optics and accessories included. Visit our store for more details about the cnCam-e and take advantage of this special promotional offer while it lasts.

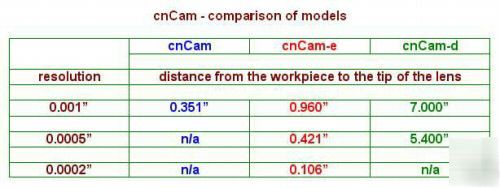

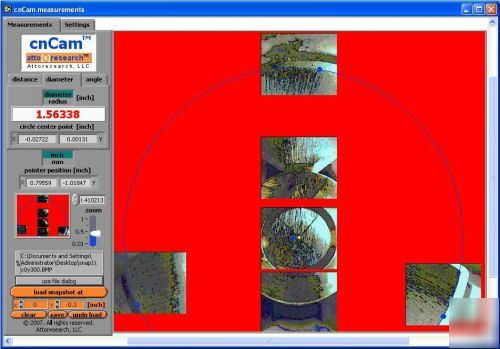

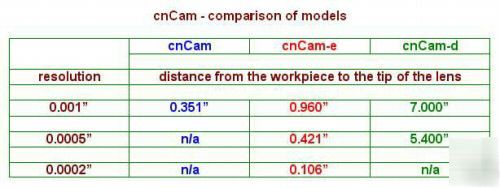

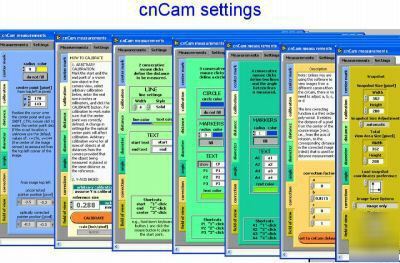

cnCam-d is capable of 0.0005" resolution from a distance of 5.4 inches and 0.001" from 7 inches. It is a 20 times bigger distance from the workpiece than for the original cnCam. This opens many application possibilities that were not feasible before. cnCam-d comes with a powerful on-screen measurement software that is capable of performing measurements over 1Gpixel field of view. It translates to 32"x32" at 0.001" resolution.

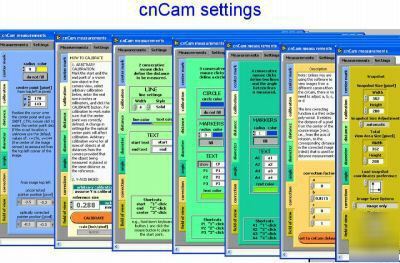

Visit our store for more details about the software.

The product combines a state-of-the-art, high-performance USB camera with a high precision, highly concentric mechanical design that allows you to:

1. Align the axis of rotation of your machine with a reference point on your workpiece to within +/-0.00025", guaranteed. U.S. Patent pending.

2. Observe and make calibrated on-screen measurements under high magnification (up to x82 on a 19" screen) and with high resolution (up to 0.0005"). Adjustable focus lets you choose a resolution that is appropriate for the job - from 0.0005", through 0.001"- and up to infinity if a larger field of view is needed.

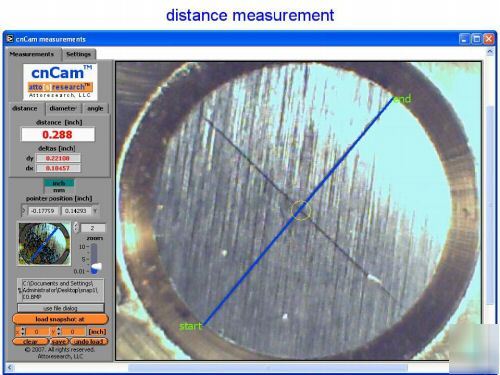

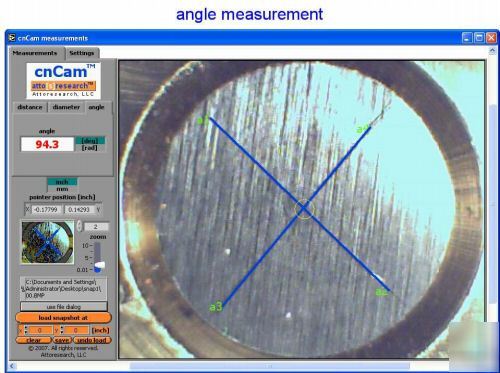

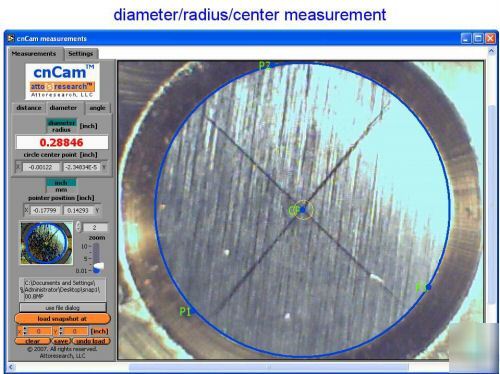

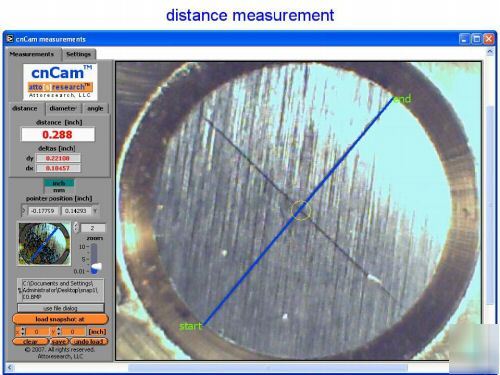

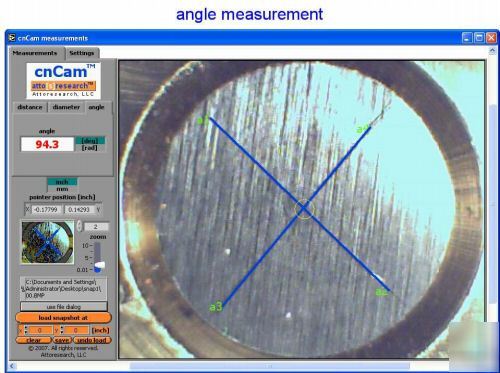

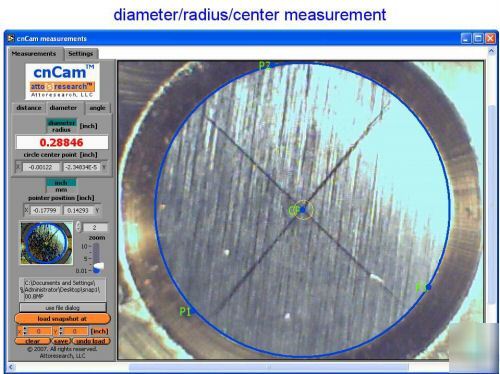

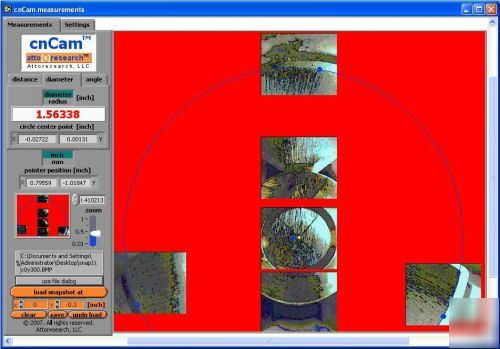

3. Find position, distance, diameter/center, or angle using 1-, 2-, 3-, or 4-point based automatic on-screen measurements.

4. Calibrate on-screen measurements for objects of any size and distance from the camera.

5. Precisely position a workpiece on the machine's table.

6. Evaluate rigidity and repeatability of your machine.

7. Convert your digital-readout or cnc milling machine into a precision CMM system.

8. Create cnc-based 3- or 4- axis machine inspection systems.

9. Follow inkjet or laser printout of a required toolpath to manufacture single quantities of precision parts on manual or cnc mills without programming and without backlash problems.

10. Observe your mill's performance up close from a safe place in front of your PC .

11. Take snapshots or capture full motion videos.

Quality inspection, measurement, and diagnostic tool with industrial, laboratory, medical, and many other applications.

Use it on laptops, PCs, and selected models of PDAs.

On-screen measurement software with sophisticated correction of lens distortions is included. Snapshot button on the camera - no access to the keyboard is needed to start the application software and/or to capture images.

NIST traceable shank within the size tolerance of 0.0002 (class ZZ or better) for very good insertion repeatability and runout less than 0.0001". Class X shank (0.000040") available per request (add $35).

52100 bearing steel hardened to 60-62 Rockwell C with a 10 microinch finish or better (2 microinch for X class).

Overall camera concentricity better than 0.0005

Focus from 4 or less to infinity.

Camera field of view starts from 0.144 diameter (translates to 0.0005 per pixel on screen). The incoming video can be resized to use the full PC screen resolution (typically 1024 x 768 or 1280 x 1024) making it easy and comfortable to operate the equipment at the 0.0005 resolution level.

Sensor array: 352 (H) x 288(V).

Flexible illumination system. 100,000 hour life expectancy white LED, 25mA.

Safety cable disconnects (in case the spindle drive is accidentally turned on).

Power consumption: < 25mA (camera) plus 25mA LED light if used.

USB cable, PC drivers (for Microsoft Windows Vista, XP, W2K, W98SE/ME), on-screen manual, and image/video processing software are included.

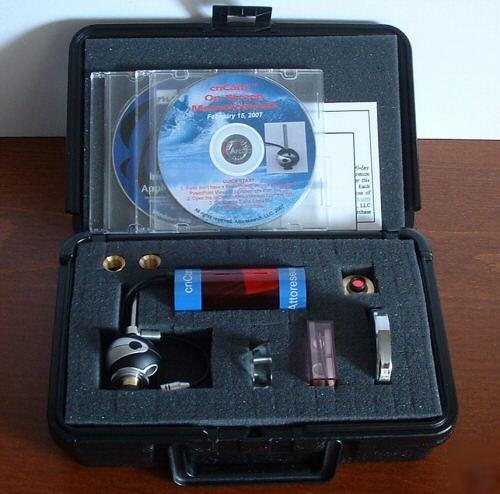

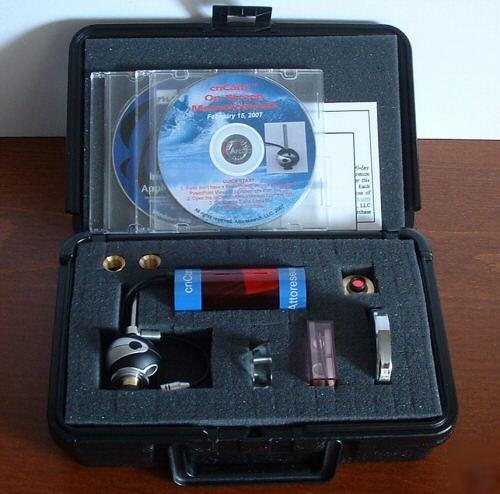

The camera with a flexible illumination system.

On-screen measurement software.

Platt #207 case with a foam insert to hold and to protect all components.

1/4" to 3/8" converter for placing the camera in an instrument holder. Instrument holder is used for following inkjet printouts and/or for adjustments to the milling machine.

Magnetic bay. Holds the camera firmly attached to the mill when not in use. The camera will be there and ready to work when needed.

A 2mm and a 0.035" hexagonal wrenches, and

The camera uses a system on a chip CMOS image sensor with an embedded USB interface and image compression hardware. No external components such as power supplies or amplifiers are needed. Just connect the camera to a PC. All image processing functions, such as interpolation, auto exposure, auto white balance, de-flickering, and sharpness are performed by software on the PC side.