Machine Parts For Reuse Newsgroup Discussion Forum > Medium Size Parts

> New

> Electronic

> Chicago

> Arrowhead rockdrill hydraulic hammer/breaker- usa made

Arrowhead rockdrill hydraulic hammer/breaker- usa made

MADE IN THE UNITED STATES OF AMERICA

RECENT SALES BY FEL-TECH HAMMER DIVISION

NOW USED BY THE ARMY CORPS OF ENGINEERS

NOW USED BY THE NATIONAL CIVIL GEOTECHNICAL, ROCK AND WATER RESOURCES

NOW USED IN PIPE LINE INSTALATION IN SABA, NETHERLAND ANTILLIES

NOW USED IN MEXICO FOR PROPANE TANK INSTALLATIONS

NOW USED IN MINING OPERATIONS IN AFRICA

NOW USED IN FACING OPERATIONS IN RUSSIA

NOW USED IN MANY RENTAL HOUSES WORLDWIDE

PURCHASE WHAT OTHER PROFESSIONAL CONTRACTORS ARE NOW USING

BY THE HYDRAULIC HAMMER ASSOCIATION OF AMERICA FOR THE YEAR 2010

Field tested and proven for over 25 years

Corporate Office-United States

We will include an extra tool bit at no charge

FEL-TECH Hammer Division now offers

ARROWHEAD ROCKDRILL HYDRAULIC HAMMERS

You know FEL-TECH Hammer Division as your worldwide source for hydraulic hammer wear parts for over 1500 models of hydraulic hammers. You know FEL-TECH Hammer Division as the largest hydraulic hammer wear parts center in the world.

YOUR NEW AMERICAN MADE ARROWHEAD ROCKDRILL HYDRAULIC HAMMER WILL ARRIVE WITH THE FOLLOWING ITEMS AND SUPPORT.

1. TWO NEW AMERICAN MADE CHISELS OR MOIL POINTS (MIX OR MATCH)

2. NITROGEN CHARGE KIT WITH INSTRUCTIONS

3. A NEW PIN MOUNTED TOP BRACKET (OTHER BRACKETS AVAILIABLE)

5. A NEW BATTERY POWERED GREASE GUN

11. WORLDWIDE INSTALLATION SERVICES (QUOTES ARE AVAILIABLE)

5 A.M EST 5 P.M. PST EMAIL SUPPORT AT SALES@FEL-TECH.COM

IMPACT RATE 550 - 1200 Adjustable Variable Speed

CARRIER WEIGHT 9000 - 18700 LBS

"IN ORDER TO OBTAIN A GLOBAL REPUTATION, FEL-TECH AND OUR WORKING PARTNER MUST EXCEL"

Contractors around the world know and trust FEL-TECH Hammer Division for their products and their high standards when it comes to offering new hydraulic hammers.

ARROWHEAD ROCKDRILL HAS EXCEEDED OUR STANDARDS

NOW WE HAVE SET OUR STANDARDS EVEN HIGHER

During the last thirty years ARROWHEAD ROCKDRILL CO. has established itself as a world-class manufacturer of Construction Attachments including Hydraulic Hammers, Compaction Products and various accessories.

ARROWHEAD ROCKDRILL has a very strong history of representing and building hydraulic hammers as a private label for heavy equipment manufactures. These companies have become synonymous with some of the leading names in the manufacturing of heavy equipment. When a leader in heavy equipment manufacturing chooses ARROWHEAD ROCKDRILL as their hydraulic hammer of choice it's no wonder that FEL-TECH Hammer Division must offer the very best also.

WELCOME TO ARROWHEAD ROCKDRILL AND FEL-TECH HAMMER DIVISION

ARROWHEAD S60 LIGHT RANGE HYDRAULIC HAMMER

THE ARROWHEAD ROCKDRILL HAMMER CAN LITERALLY PAY FOR ITSELF

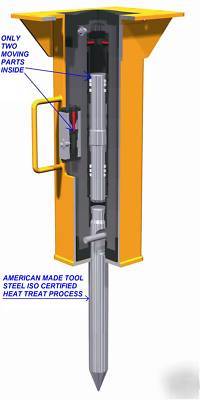

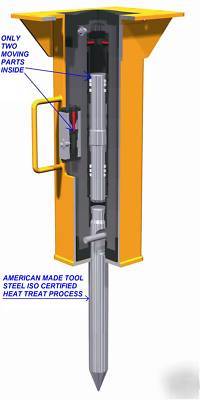

Based on proper use and maintenance with the increased blows per minute, your new ARROWHEAD ROCKDRILL hammer can pay for itself over time because the hammer has only two moving parts. This means when you do rebuild your ARROWHEAD ROCKDRILL HAMMER your replacement parts cost will be considerably less. The amount of parts that you will be replacing is less. This means more money in your pocket. In most cases a new seal kit is installed and you can be operational by the end of the day.

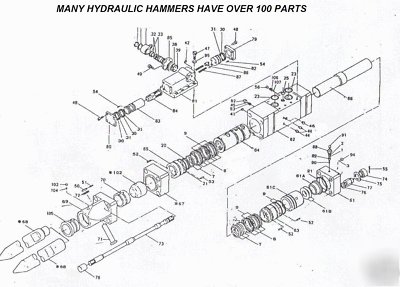

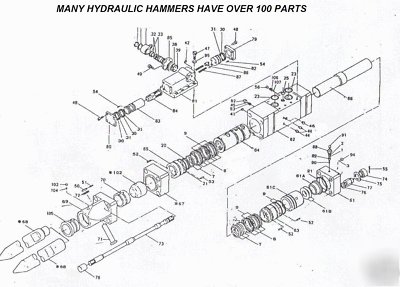

Other hammers are very complicated and the parts list can be several pages

Many hammers have over 100 separate parts

There are only THREE reasons why other manufacturers have so many internal parts

Idle engineers need to substantiate their job. Therefor, unnecessary improvments are made to justify their positions.

The manufacturer also relizes that the more parts inside your hammer, the greater chance it will break after the warranty is over.

The manufacturer wants your rebuild work after the hydraulic hammer fails because it is most likely to complicated for the average mechanic to rebuild.

THIS MEANS YOU WILL SPEND HUNDREDS OR THOUSANDS OF DOLLARS AGAIN!

ARROWHEAD ROCKDRILL HAS ONLY TWO INTERNAL MOVING PARTS

ARROWHEAD ROCKDRILL CAN BE OPERATED AT A LOWER ENGINE IDLE

ARROWHEAD ROCKDRILL BUILDS THEIR OWN TOOL BITS IN THE USA

ARROWHEAD ROCKDRILL HAS NO DEPENDENE ON KOREA

"ARROWHEAD ROCKDRILL IS AMERICA'S HYDRAULIC HAMMER"

ARROWHEAD ROCKDRILL has designed their hydraulic hammer to break rock. The more moving parts in a hydraulic hammer will always increase potential problems and repair cost. Many hydraulic hammers CANNOT be rebuilt by the average in house mechanic or small contractor because special measuring devices are required even before a rebuild is considered. ARROWHEAD ROCKDRILL hydraulic hammers are designed to be user friendly, contractor rebuildable and cost effective to own and operate. This allows the general contractor, rental house, municipality and the home based contractor a greater advantage to succeed with a greater profit margin AND less downtime.

When a contractor looks for a new hydraulic hammer, the selection can be very confusing except when you choose an ARROWHEAD ROCKDRILL PRODUCT. With over 60 different hydraulic hammer names on the worldwide market and over 1500 models, it s no wonder why more and more contractors rely on the reputation of FEL-TECH Hammer Division to recommend the best hammer for the toughest projects. Cost, quality, ease of maintenance and your production rates are our top priority. At ARROWHEAD ROCKDRILL this same philosophy has been the foundation that has made ARROWHEAD ROCKDRILL A WORLDWIDE LEADER in hydraulic hammers.

Contractors around the world know and trust FEL-TECH Hammer Division for their products and their high standards when it comes to offering new hydraulic hammers and also rebuilding hydraulic hammers.

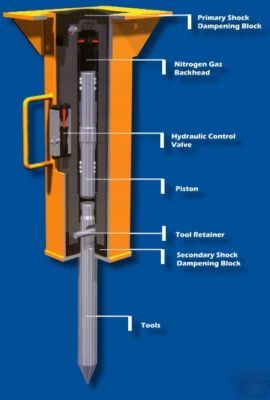

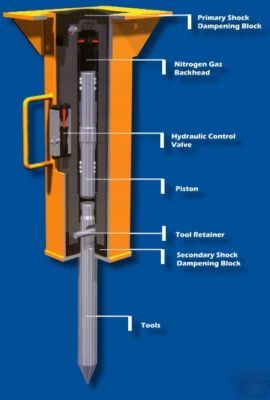

Only Two Moving Parts Inside The Hammer

THE HYDRAULIC CONTROL VALVE AND THE PISTON

ARROWHEAD ROCKDRILL has designed their hydraulic hammer to break rock. The hammer breakdown in the picture gallery depicts a competitor s hydraulic hammer that is designed to break rock. The more moving parts in a hydraulic hammer will always increase potential problems and repair cost. Many hydraulic hammers CANNOT be rebuilt by the average in house mechanic or small contractor because special measuring devices are required even before a rebuild is considered. ARROWHEAD ROCKDRILL hydraulic hammers are designed to be user friendly, contractor rebuildable and cost effective to own and operate. This allows the general contractor, rental house, municipality and the home based contractor a greater advantage to succeed with a greater profit margin AND less downtime.

WITH ONLY TWO MOVING PARTS INSIDE, ARROWHEAD ROCKDRILL HAS A USER FRIENDLY DESIGN THAT ALLOWS ALL CONTRACTORS TO DO THEIR OWN REBUILD WITHOUT HESITATION

High operating cost per use hour will always remove dollars from your profit!

FEL-TECH Hammer Division is known as a premiere rebuild center and has always looked at the cost per use hour on the models of hydraulic hammers that we rebuild and the new hydraulic hammers we are proud offer.

FEL-TECH Hammer Division does the homework for you

INITIAL COST OF HAMMER + FUTURE ESTIMATED REBUILD COST / DIVIDED BY ESTIMATED 1,000 HRS USE = COST PER OPERATING HOUR

(Based on data received in average test studies)

Hammer brand: A Initial cost of a new (brand name) 850 lb. hammer $ 10,600.00

Potential rebuild estimated cost 4,300.00

Cost per hour of use (based on 1,000 hrs use) $14.90

ARROWHEAD Initial cost of a new ARROWHEAD hammer 850 lb. $8,300.00

Potential rebuild estimated cost 2,200.00

Cost per hour of use (based on 1,000 hrs use) $10.50

*Estimated savings for your company $4,400.00

REBUILD YOUR ARROWHEAD ROCKDRILL AT YOUR SHOP AND SAVE APPROXIMATELY $1600.00

YOUR POTENTIAL SAVINGS IS NOW $ 4,400.00

FEL-TECH Offers Financing for up to 5 Yrs

Construction equipment leasing also offers tax advantages. Construction equipment leasing increases your liabilities and that translates into a lower tax burden to the IRS.

FEL-TECH Hammer Division relies on the quality of ARROWHEAD ROCKDRILL as a working partner as we represent ARROWHEAD ROCKDRILL and supply contractors with the ARROWHEAD ROCKDRILL line of hydraulic hammers.

ARROWHEAD ROCKDRILL HAS STARTED FROM THE BEGINNING WITH THE IDEA THAT A BETTER TOOL COULD BE PRODUCED WITH QUALITY PRODUCTS, UNIQUE ENGINEERING PRACTICES, HARD WORK, FAIR BUSINESS PRACTICES AND LONG LASTING PRODUCT QUALITY. SOON A QUALITY HYDRAULIC HAMMER WAS INTRODUCED THAT WOULD CHANGE THE INDUSTRY IN EUROPE AND THE UNITED STATES OF AMERICA

Many start-up hydraulic hammer companies simply take a flight to Korea on a Monday and by the end of the week we now have a new model in the United States market. Simply change the case, add a few gussets to the case, and spray paint it a color of choice and then ADD YOUR OWN LABEL. Where did the hammer actually come from? What is the real name? What is the real model number? Who is the TRUE MANUFACTURER?

WILL THE SELLER BE HONEST WITH YOU AND TELL YOU THAT IT JUST CAME OFF THE BOAT, IT'S DRIPPING WITH WET PAINT AND IT JUST CAME FROM "WE MAKE YOU TOO HAPPY" HAMMER COMPANY?

WILL PARTS BE AVAILABLE FOR YOU ONE OR TWO YEARS FROM NOW?

WILL THE COMPANY BE OPEN ONE YEAR FROM NOW?

ARROWHEAD ROCKDRILL has real OEM parts. Other major manufacturers also have OEM parts that are not called OEM until they leave a foreign country and land on American soil. The parts are made for pennies on a dollar but sold at unaffordable prices.

ARROWHEAD ROCKDRILL has no dependence on other factories to manufacture ARROWHEAD parts. All parts are OEM and made in the United States of America.

ARROWHEAD ROCKDRILL has a 30 year history of manufacturing in the hydraulic hammer industry. This is a proven reliability based on years of experience.

ARROWHEAD ROCKDRILL has never been sold to a larger concern and re-labeled.

ARROWHEAD ROCKDRILL is the only manufacturer that manufactures their own tool steel in the United States.

ARROWHEAD ROCKDRILL is the only hydraulic hammer company that has complete machine shops at many of their dealer s facilities around the world. This means that the ARROWHEAD ROCKDRILL dealer has a true understanding of what he is selling when discussing the steel case, the piston s impact energy, the tool steel quality and the small amount of wear that takes place as your production rate is surprisingly increased as you use your new ARROWHEAD ROCKDRILL HAMMER.

.ARROWHEAD ROCKDRILL eliminates the need for additional in line accumulators.

ARROWHEAD ROCKDRILL has a 75% increased production rate when contractors are breaking rock.

At FEL-TECH Hammer Division we are always pleased to accept your ARROWHEAD ROCKDRILL HAMMER in trade if you upgrade or downgrade your carrier size.

ARROWHEAD ROCKDRILL Hydraulic Hammers - Key Product Advantages

Each key selling point has been expanded to give more background on each particular point:

- VERY FEW COMPONENTS: For example S50 power cell only has 20 components (excluding seals, nuts & bolts)

- NO SPECIAL TOOLS ARE REQUIRED TO ASSEMBLE /DISASSEMBLE THE BREAKERS: The only special tool required is a gas charging kit to charge the hammer.

- ONLY 2 QUICK & SIMPLE CHECKS NEEDED:

i. Check all bolts for tightness.

ii. Lubricate tool and tool holder every 2 to 3 hours.

- No cross-bolts to bend break or work loose. THE END RESULT IS: NO DOWNTIME.

- The hammer is held in place by State-of the-Art Polymer Centralizing System.

- Protects hammer mechanism from damage.

i. This eliminates physical damage to the power cell.

ii. Protects tie rods reducing breakage due to side loading.

3. Only two (2) Moving Parts piston & valve assembly

- With less moving parts this means less to go wrong!

4. High Impact Energy Consistently Through Engine Rev Range

- The hammer hits as hard, with maximum impact energy, on every blow whether it is hitting at 1 or 1000 blows per minute. This is a very important feature when a precise area of material must be removed during any finish work. With many hammers on the market today the impact energy must be increased after operating the hammer momentarily and then you achieve the full impact energy. This may remove more product than you anticipated which will lead to a possible repair at your cost.

5. Vibra-Silencing reduces operator and carrier machine vibration exposure

- Eliminates the majority of the vibration and shock generated by the hammer to protect the machine minimizing wear and tear, keeping DOWNTIME to a minimum. Replacement parts for your machine are also very costly. Why abuse your carrier of the hammer and create even more lost profits.

- Operator Friendly : limits noise and vibration emitted by the breaker making the use of the breaker more comfortable for the operator; while at the same time reducing the sound impact of operating breakers in built up, urbanized areas. This means an earlier start on your project and even a later work day if you chose to do so.

6. Direct Acting Nitrogen Gas Back Head

- Delivers more power than other types of breaker as the piston fires directly into the nitrogen back head providing a more efficient transfer of impact energy from the back head to the piston.

- Eliminates the need for additional in line accumulators.

7. Speedy nitrogen recharge process

- As complicated as inflating a car tire! Gas charging can be completed in less than 5 minutes while the hammer is still in the field if necessary. Re-gassing these hammers is quick, easy and simple. This feature is very important because you do not have to send your hydraulic hammer back to the dealer by truck because you do not have that special tool and complicated device that many dealers purposely design and offer in order to create more revenue for their company.

8. Lower Guaranteed Sound Power Levels

- As a result of the Vibra-Silencing system these hammers emit much less noise than other competitive hammers using the older side plate technology. This is particularly important for applications in urban areas.

9. Easily Maintained Through Single Greasing System

- The centrally located grease point feeds essential lubrication to all areas of the tool housing prolonging tool life and keeping the hammer working longer. Many dealers have grease ports that send grease to the tool BUT the grease also does not get dispersed in a fashion that reduces the tool life.

- Compact Equipment demands Compact Attachments! The slim line profile of these machines makes using a hammer possible in previously inaccessible areas, allowing the operator to work more effectively improving productivity saving time and money.

- The structural integrity of a boxed hammer bracket is considerably greater than side plate constructed hammers.

Overview of Key Product Advantages Arrowhead Rockdrill Hammers

* Less component parts than most competitors

* Less parts - Less to go wrong

* Powerful direct acting N2 gas back head

* Vibration & sound suppression system included as standard by the use of oversized polyurethane buffers

* Strong, lightweight design

* Elimination of cross bolts which increases reliability

* Quick change tool retainer system

* Superior protection of the power cell

* Improved tie rod protection

* Clean, simple appearance

* Can be fully rebuilt to as new specifications

* Same production for less

* Benefit: Run the excavator at lower engine revolutions

* Benefit: Reduces wear and tear on excavator

A HIGH QUALITY HYDRAULIC HAMMER WITH VERY LOW MAINTENANCE COST THAT IS COMPETITIVELY PRICED.

Visit our web site for more information about Arrowhead Rockdrill hydraulic hammers: http:// /

For more information about Arrowhead Rockdrill you ay contact :

Worcester, Massachusetts 01606