Machine Parts For Reuse Newsgroup Discussion Forum > Large Size Parts

> Non functional

> Electronic

> Maiami

> New reliance 841XL 75 hp 365TSC 3600RPM c-face

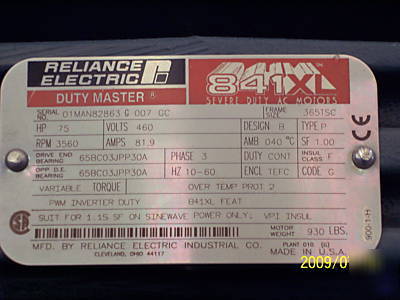

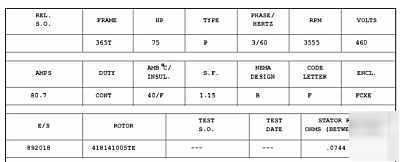

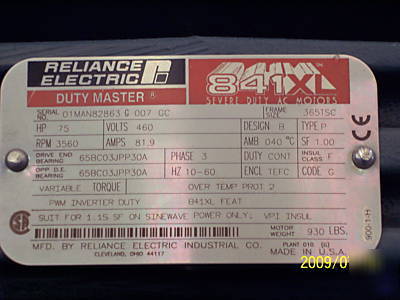

New reliance 841XL 75 hp 365TSC 3600RPM c-face

Reliance 841XL Premium Efficient AC Motors

* Longer bearing life with PLS lubrication system.

Positive Lubrication system directs the grease through the raceways and purges contaminates out the relief channel. Reliance XT motors also have internal cast iron bearing caps to allow the use of open bearings. This allows more grease to enter and lower operating temperatures.

* Silicon Sealant in the fits keeps contaminants out.

XT Motors have a longer end bracket to frame fit. Also silicon sealant is put in this fit to insure contaminates can not enter the interior of the motor and meet the IP standard of IP54 or 55.

* Stainless "T" drains make maintenance easier.

Stainless "T" drains installed in each end bracket have a special relief path to allow condensation to drain without the need to remove a plug.

* Coated interior surfaces protect the stator and rotor from corrosion.

An epoxy coating is put on the surface of both the rotor and stator. This helps protect the internal parts of the motor from corrosive atmospheres.

* A labyrinth non contact seal protects the bearing and extends the life of the motor.

841 Motors have special "Inpro" type seal to keep contaminants and liquids from the bearing and meet the requirement for IP55 bearing protection.

* Cast Iron Fan cover will last longer

The Cast iron fan cover is heavier and has better resistance to flying debris and corrosive atmospheres and is required by IEEE841.

* Cast Iron Conduit Box will last longer.

The cast iron conduit box is heavier and has better resistance to flying debris and corrosive atmospheres and is required by 841.

* Stainless Steel nameplate with raised letters will stay readable.

The nameplate is made with 304 stainless steel. Stainless steel resists corrosion and will be readable longer than standard aluminum or steel nameplate. This is required to meet the specification.

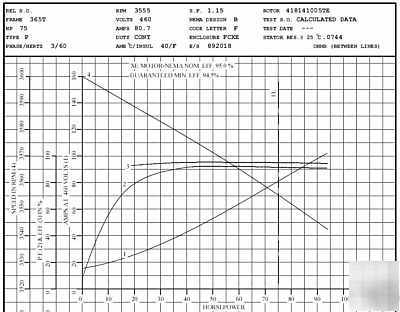

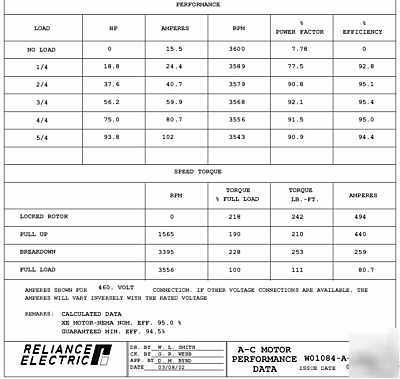

* Premium Efficient electrical design saves money.

Premium efficient motors will lower operating cost with higher efficiency. The design will have more active material (copper and steel) and specially designed rotor slots. Both of these results in lower losses and higher efficiency of power put in the motor.

* Premium Efficient electrical design last longer.

Lower losses in the windings mean the motor will run cooler. This will increase both bearing life and the life of the insulation systems when compared to standard efficient design.

* Flat foot is easier to align and reduces maintenance and improves life.

Foot flatness is restricted by IEEE841 .0005 inches. Very flat feet insure a good base for aligning the motor with the driven equipment. Better alignment of the motor and equipment will make the bearings last longer.

* Less shaft vibration improves bearing life.

IEEE841 requires .08 rotor balances (inches per second peak to peak). Reliance 841 motors have .04 inches/ sec which will reduce the vibration seen at the bearings and improve life.